TruMatic 7000

Innovative Punch Laser Technology

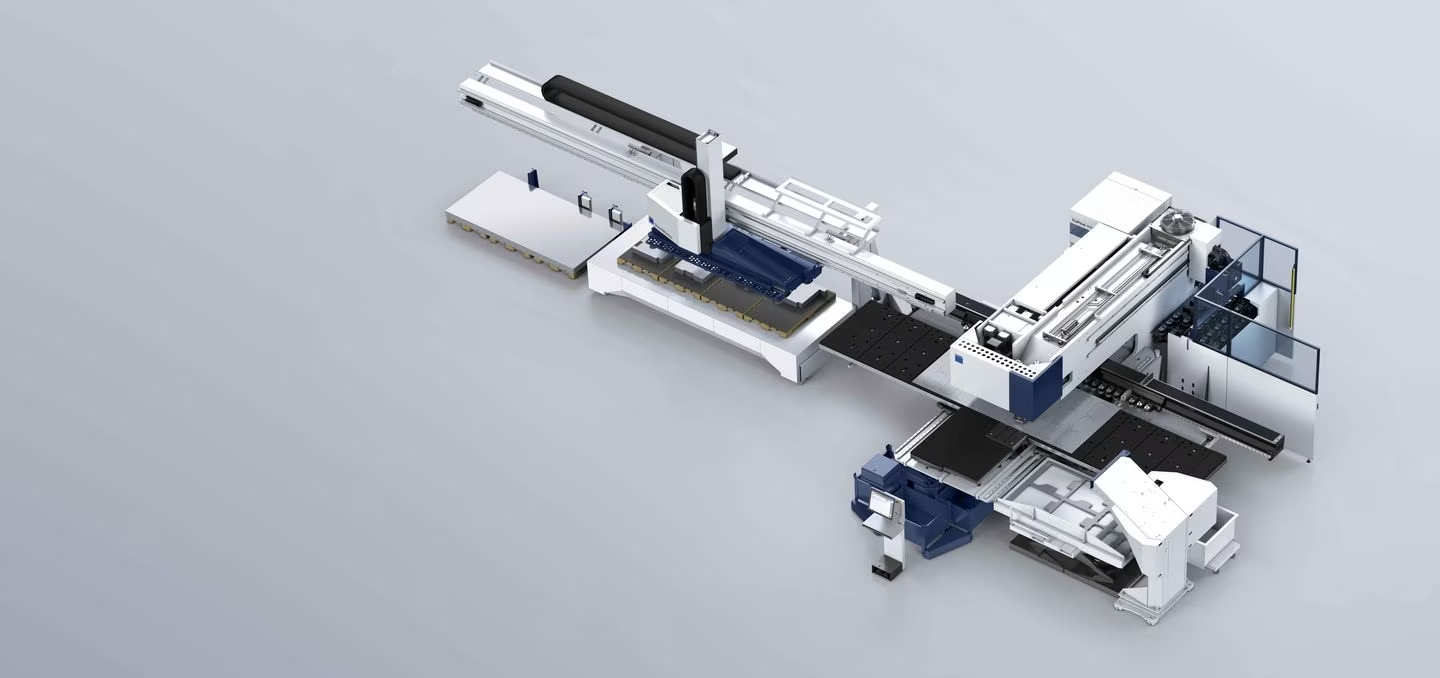

Discover the power of the TruMatic 7000, a cutting-edge punch laser machine from TRUMPF. Combining laser technology's precision with punching efficiency, this machine sets a new standard in metal fabrication. Whether you’re working with steel, aluminum, or other metals, the TRUMPF TruMatic 7000 offers unparalleled versatility and performance to meet the demands of modern manufacturing.

Applications Best Used For

The TruMatic 7000 is best used for high-precision sheet metal processing in the automotive, aerospace, and general manufacturing industries. Its ability to handle a variety of materials and thicknesses allows consistent, high-quality results across all applications.

Equipment Details

The TruMatic 7000 is built to deliver top-notch performance with robust construction and state-of-the-art components. Its innovative SheetMaster automation system enhances productivity by automating sheet handling, while dual carts facilitate efficient loading and unloading. The machine’s compact design ensures it fits seamlessly into any production environment.

TruMatic 7000 Technical Data

TruMatic 7000 Medium Format

TruMatic 7000 Large Format

DIMENSIONS

WIDTH

DEPTH

HEIGHT

10190 mm 1

8898 mm 1

2328 mm 1

10190 mm 1

8450 mm 1

2328 mm 1

MAXIMUM STROKE RATE

PUNCHING (E = 1 MM)

1200 1/min

1200 1/min

WORKING RANGE

PUNCHING MODE, X-AXIS

PUNCHING MODE, Y-AXIS

LASER OPERATION, X-AXIS

LASER OPERATION, Y-AXIS

COMBINED OPERATIONS, X-AXIS

COMBINED OPERATION, Y-AXIS

MAXIMUM SHEET THICKNESS

MAXIMUM WORKPIECE WEIGHT

MAXIMUM PUNCHING FORCE

3050 mm

1550 mm

3050 mm

1550 mm

2500 mm

1550 mm

8 mm

280 kg

220 kN

2500 mm

1250 mm

2500 mm

1250 mm

2500 mm

1250 mm

8 mm

200 kg

220 kN

TOOLS

MULTITOOL TOOL CHANGING TIME

0.3 s

0.3 s

NUMBER OF TOOLS/CLAMPS

21 pieces / 4 pieces

22 pieces / 3 pieces

LASER-SPECIFIC DATA TRUFLOW 4000

MAXIMUM LASER POWER

MAXIMUM SHEET THICKNESS, MILD STEEL

MAXIMUM SHEET THICKNESS, STAINLESS STEEL

MAXIMUM SHEET THICKNESS, ALUMINUM

4000 W

8 mm

8 mm

6 mm

4000 W

8 mm

8 mm

6 mm

PART REMOVAL

MAXIMUM PART SIZE, PART REMOVAL FLAP, PUNCHING

500 mm x 500 mm

500 mm x 500 mm

MAXIMUM PART SIZE, FIXED CHUTE, PUNCHING (WITH MOVING TABLE)

80 mm x 50 mm

80 mm x 50 mm

MAXIMUM PART SIZE, PART REMOVAL FLAP, LASER

500 mm x 500 mm

500 mm x 500 mm

3000 1/min

MARKING

3000 1/min

CONSUMPTION VALUES

AVERAGE POWER INPUT IN PRODUCTION - TRUFLOW 4000

AUTO-SHUTDOWN ACTIVE - TRUFLOW 4000

28.5 kW

1.5 kW

28.5 kW

1.5 kW

Integrate With TRUMPF’s TruTops Software

Seamlessly integrate the TruMatic 7000 with TRUMPF’s advanced software TruTops solutions for optimized performance. The intuitive interface and powerful programming capabilities make it easy to handle complex tasks, reducing setup times and enhancing overall efficiency. This integration maximizes the machine's capabilities with minimal effort.

Tool Add-Ons

Customize your TruMatic 7000 with a variety of tool add-ons from TRUMPF. The machine’s flexible tool system allows quick changes and easy adaptation to different fabrication needs. With the ability to hold multiple tools simultaneously, the TruMatic 7000 keeps you prepared for any job.

Automate Your Punching Processes

Achieve new levels of efficiency with the TruMatic 7000’s automation features. From sheet handling to part removal, every aspect of the machine is designed to reduce manual intervention and increase throughput. Intelligent automation systems not only enhance productivity but also ensure consistent, high-quality results, making your manufacturing process more reliable and efficient.

Experience the TruMatic 7000 Difference

Contact us today to learn more about the TruMatic 7000 and how it can transform your manufacturing operations.