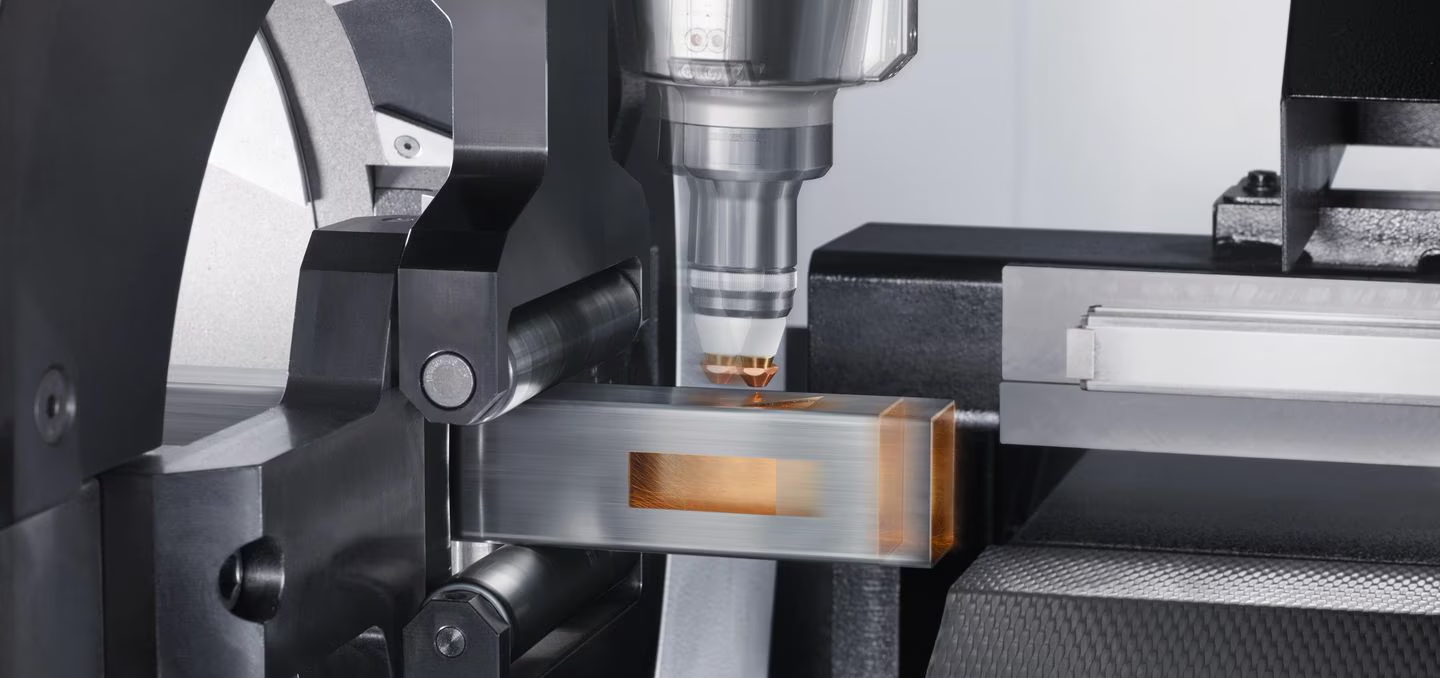

TruLaser Tube 5000 Fiber

Breakthrough Productivity with Solid-State Laser Mastery

The TRUMPF TruLaser Tube 5000 fiber is engineered for superior efficiency, speed, and precision. Designed with fabricators in mind, it’s the ideal laser tube cutting machine for complex tube and profile processing with the ability to handle even the thickest materials. With cutting-edge automation and intelligent software integration, the TruLaser Tube 5000 fiber offers optimized throughput and minimal downtime so your team can focus on delivering top-quality parts with speed and consistency.

Key Equipment Features

RapidCut Technology

Achieve superior cutting speeds on small contours, dramatically reducing part processing times.

Advanced Bevel Cutting

Precision cuts up to 45° for complex joint preparations.

Self-Centering Collet System

Automatic adjustment for various tube geometries with continuous sensor monitoring.

Automatic Step Roller System

Self-adjusting support rollers for various tube diameters.

Intelligent SeamLine Tube System

Automatic weld seam detection and internal tube scanning for optimal alignment.

Integrated Threading Capability

Direct thread-tapping functionality eliminates secondary operations.

ScanLine Technology

Real-time material tolerance compensation using light section sensors.

Smart Profile Detection

Automated recognition and processing optimization for different profiles.

Applications

With the ability to process a wide range of materials and tube profiles, the TruLaser Tube 5000 is great for a variety of applications including:

Automotive Components and Frames

Agricultural Equipment Manufacturing

Construction and Building Infrastructure

Industrial Machinery Production

Furniture and Design Applications

HVAC System Components

Metal Processing and Fabrication

Transportation Equipment Manufacturing

Fitness Equipment

Technical Specifications:

ROUND TUBE

MAXIMUM OUTSIDE DIAMETER

MAXIMUM OUTSIDE DIAMETER (Optional)

152 mm

170 mm *1

RECTANGULAR PROFILE

MAXIMUM SIDE LENGTH AND OUTER CIRCLE DIAMETER

152 mm / 170 mm

MAXIMUM RAW MATERIAL LENGTH FOR AUTOMATIC LOADING

FOR LOADMASTER TUBE 6.5 M

FOR LOADMASTER TUBE 8.0 M

6500 mm

8000 mm *3

FINISH PART LENGTH

FOR UNLOADING UNIT 3.0 m

3000 mm

FOR UNLOADING UNIT 3.0 m + 1.5 m

4500 mm *3

WORKPLACE WEIGHT

MAXIMUM PATH WEIGHT (STANDARD/OPTIONAL)

25 kg/m

MAXIMUM RAW MATERIAL WEIGHT WITH AUTOMATIC LOADING

WITH LOADMASTER TUBE 6.5 m

162.5 kg

WITH LOADMASTER TUBE 8.0 m

200 kg

FOR UNLOADING UNIT 6.5 m

6500 mm *3

FOR UNLOADING UNIT 6.5 m + 1.5 m

8000 mm *3

LASER-SPECIFIC DATA - TruFiber 4001

MAXIMUM LASER POWER

MAXIMUM MATERIAL THICKNESS, MILD STEEL

MAXIMUM MATERIAL THICKNESS, STAINLESS STEEL

MAXIMUM MATERIAL THICKNESS, ALUMINUM

MAXIMUM MATERIAL THICKNESS, COPPER

MAXIMUM MATERIAL THICKNESS, BRASS

4000 W

10 mm / 10 mm

6 mm / 6 mm

6 mm / 6 mm

5 mm

5 mm

LASER-SPECIFIC DATA - TruFiber 3001

MAXIMUM LASER POWER

6000 W

MAXIMUM MATERIAL THICKNESS, MILD STEEL

14 mm / 10 mm

MAXIMUM MATERIAL THICKNESS, MILD STEEL

10 mm / 8 mm

MAXIMUM MATERIAL THICKNESS, MILD STEEL

10 mm / 8 mm

MAXIMUM MATERIAL THICKNESS, MILD STEEL

5 mm

MAXIMUM MATERIAL THICKNESS, MILD STEEL

5 mm

MAXIMUM SIDE LENGTH AND OUTER CIRCLE DIAMETER (Optional)

180 mm / 180 mm *2

Work In Tandem With

Automation

Integrated with TRUMPF’s LoadMaster Tube, the TruLaser Tube 5000 fiber optimizes loading and unloading, minimizing manual handling and setup times. For a fully automated solution, the machine connects directly to TRUMPF’s tube storage systems, enabling efficient, high-volume workflows.

Software

The TruLaser Tube 5000 fiber works seamlessly with TRUMPF’s TruTops software, simplifying programming and process management. The Programming Tube software generates NC programs in seconds, with built-in aids for efficient, accurate design and setup.

Achieve Record Speed With The TruLaser Tube 5000

Contact us to discover how the TruLaser Tube 5000 can transform your manufacturing process and boost your productivity.