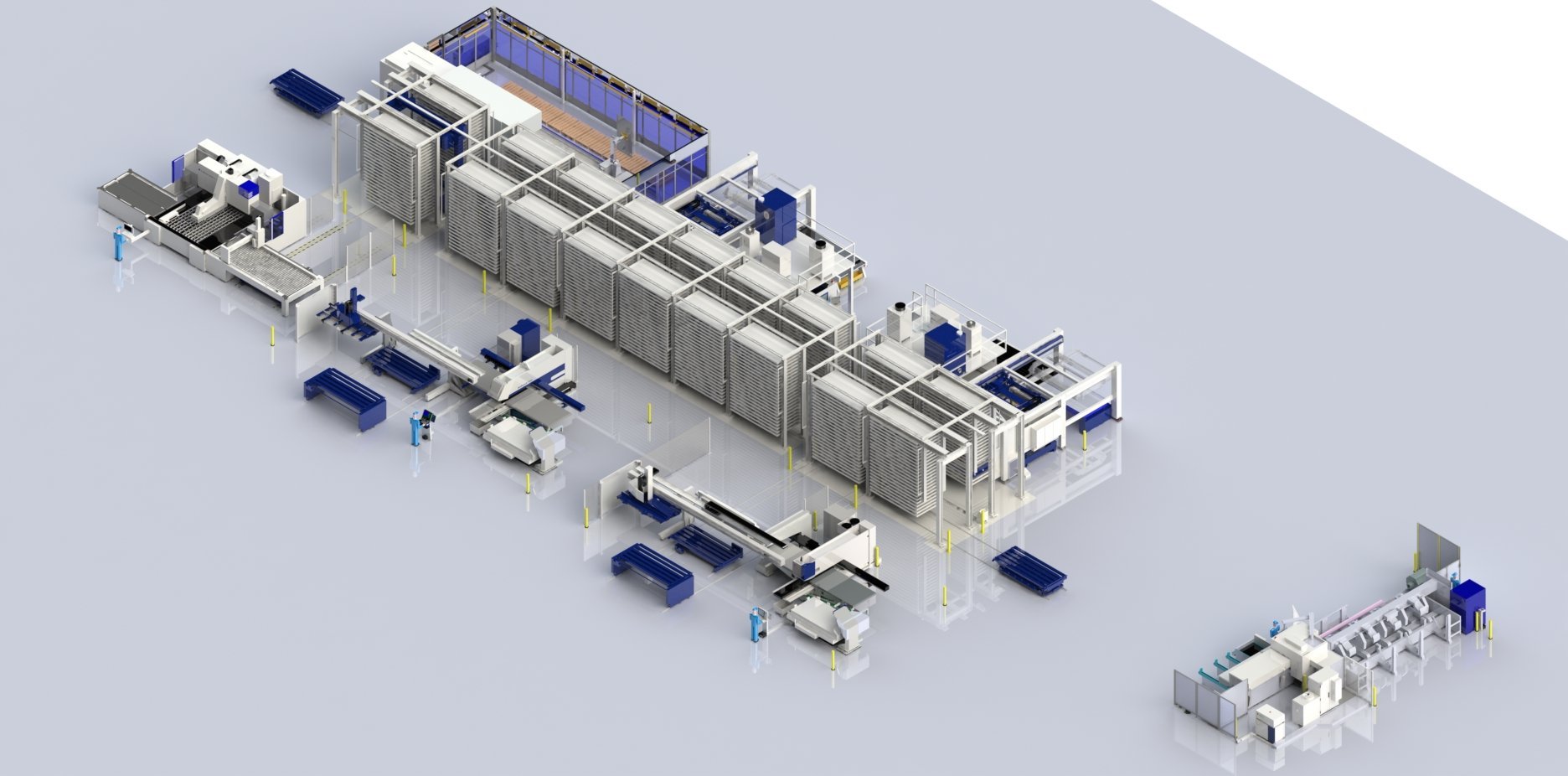

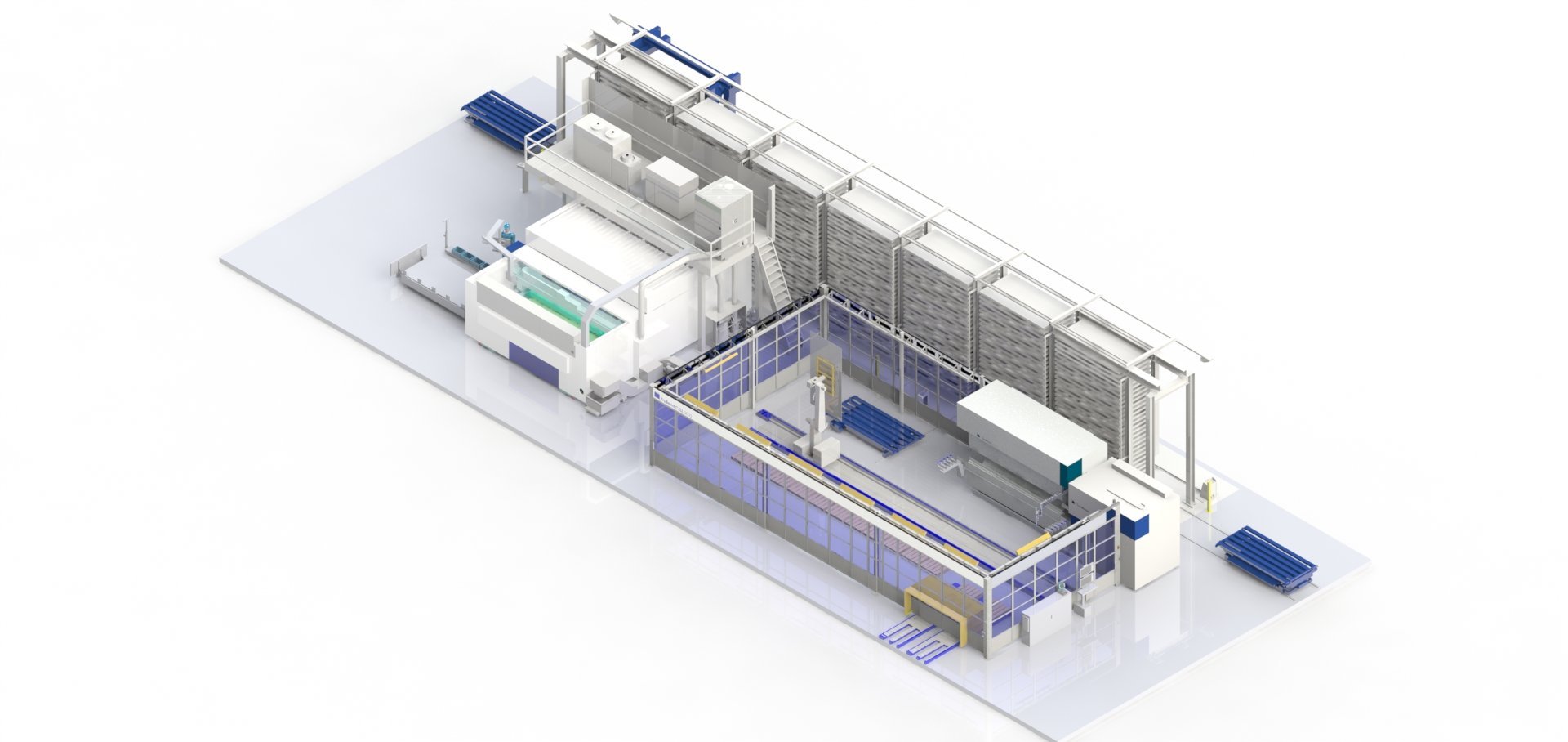

The TRUMPF Smart Factory: A Production Environment for Today and Tomorrow

It’s no secret that TRUMPF is one of the world’s foremost leaders in the fabrication and manufacturing automation space. Maintecx is proud to be the exclusive Midwest partner for TRUMPF, offering their intelligent and battle-tested vision of the metal fabrication environment. One where people, machines, and software seamlessly collaborate to create highly precise and efficient metal fabrication processes.

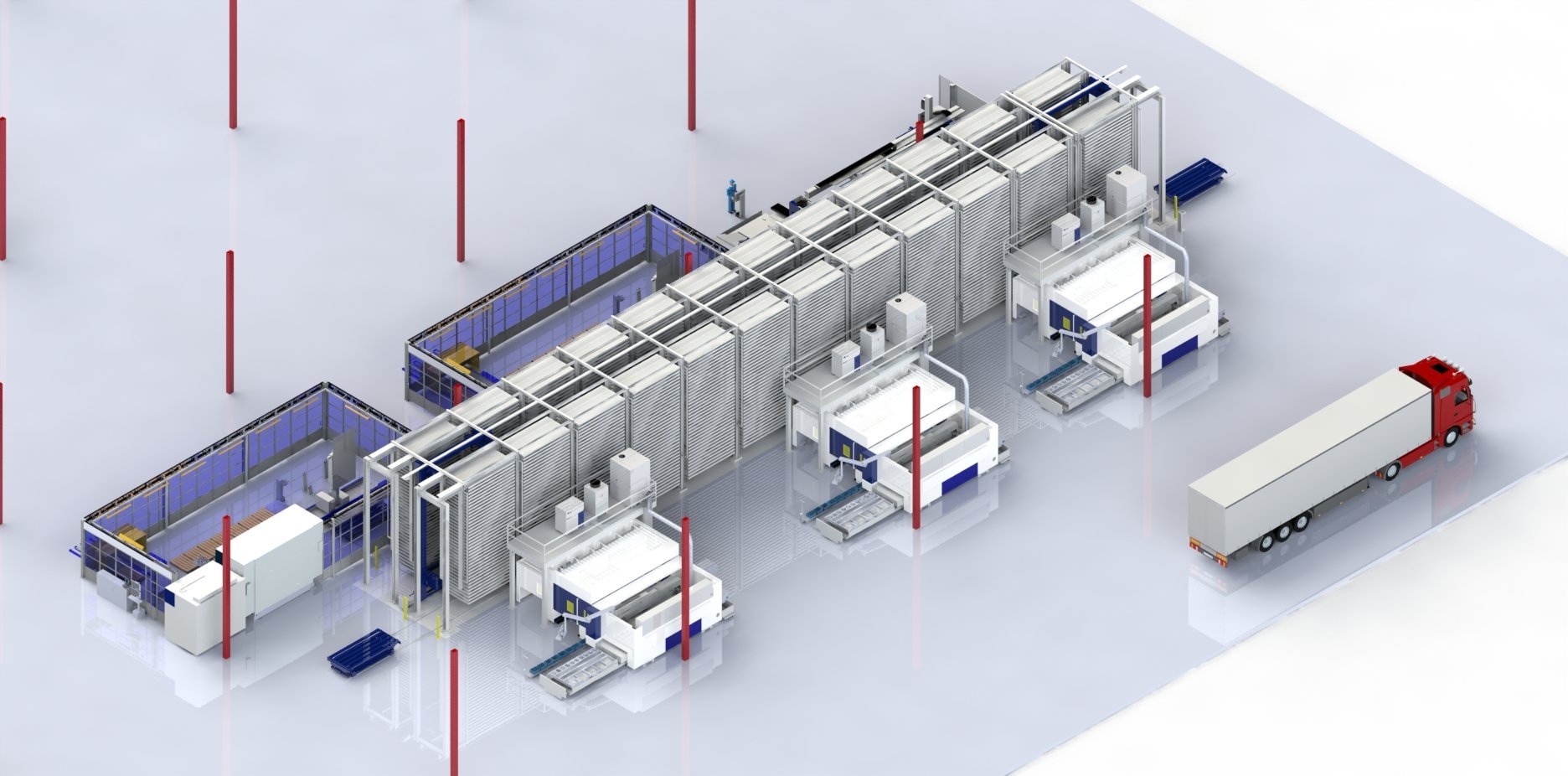

The shortage of skilled workers combined with increased international competition and interruptible supply chains has made industrial manufacturing a challenging landscape. Fortunately – there’s a solution. A completely unified manufacturing Smart Factory ecosystem that collaborates & communicates while increasing speed, efficiency, and transparency and reduces waste.

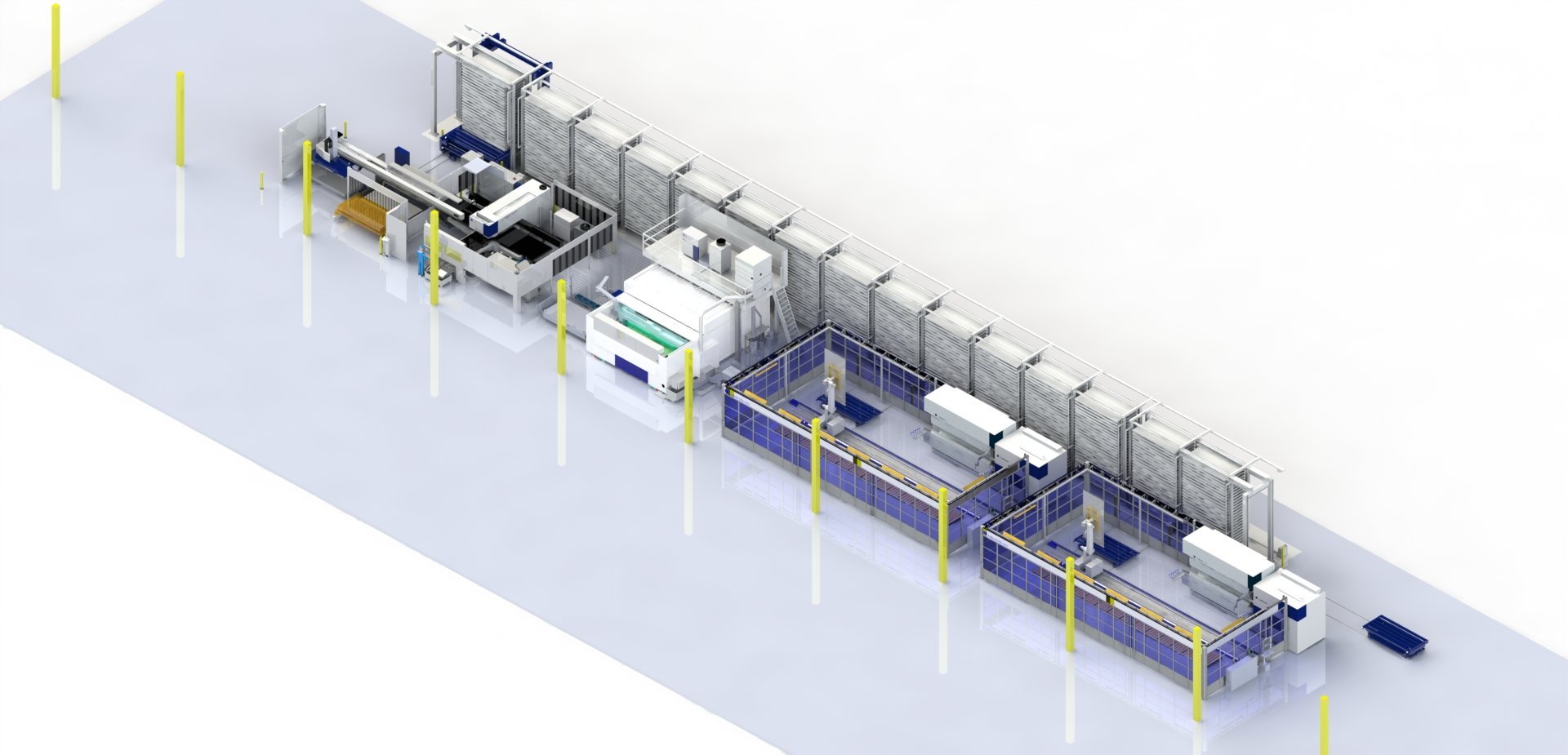

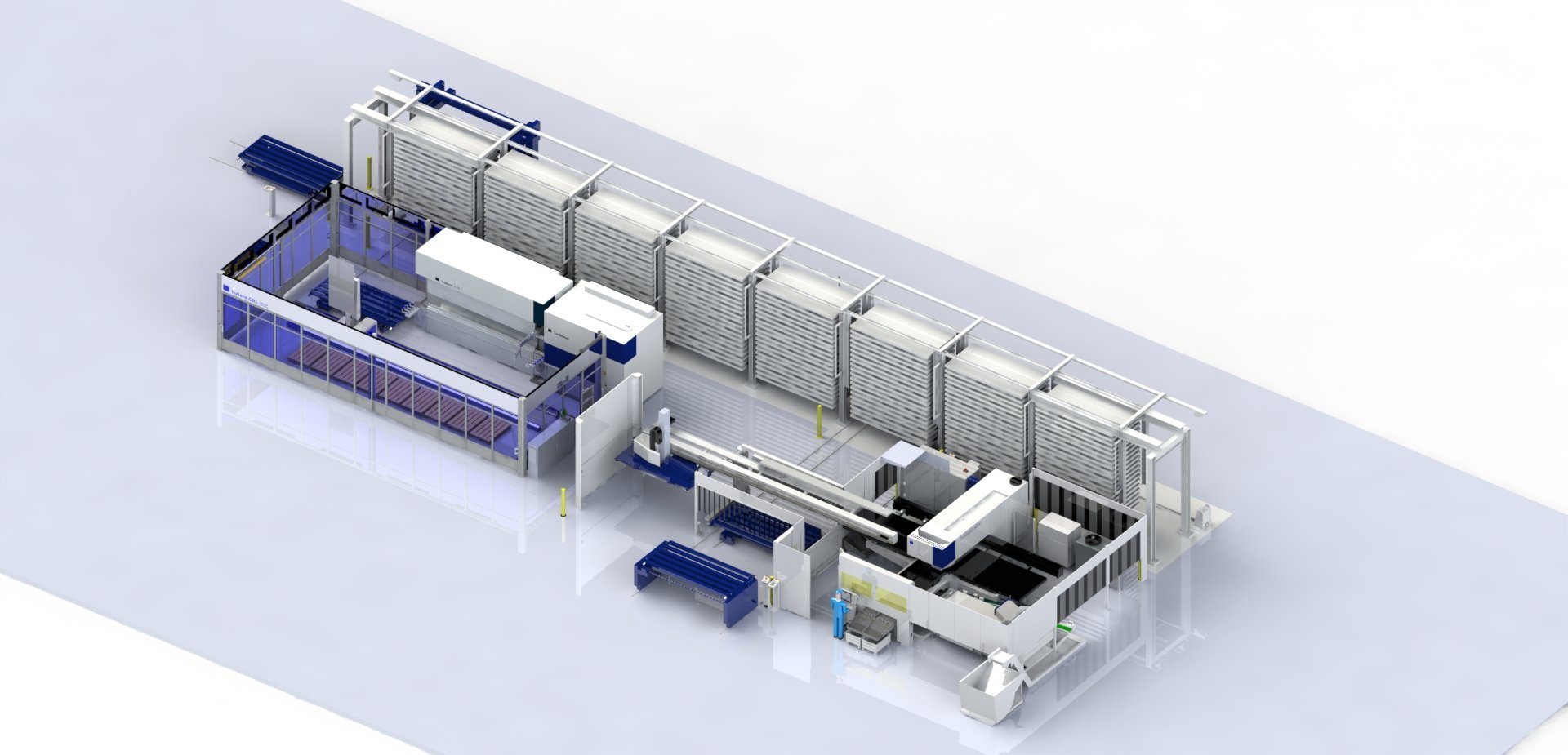

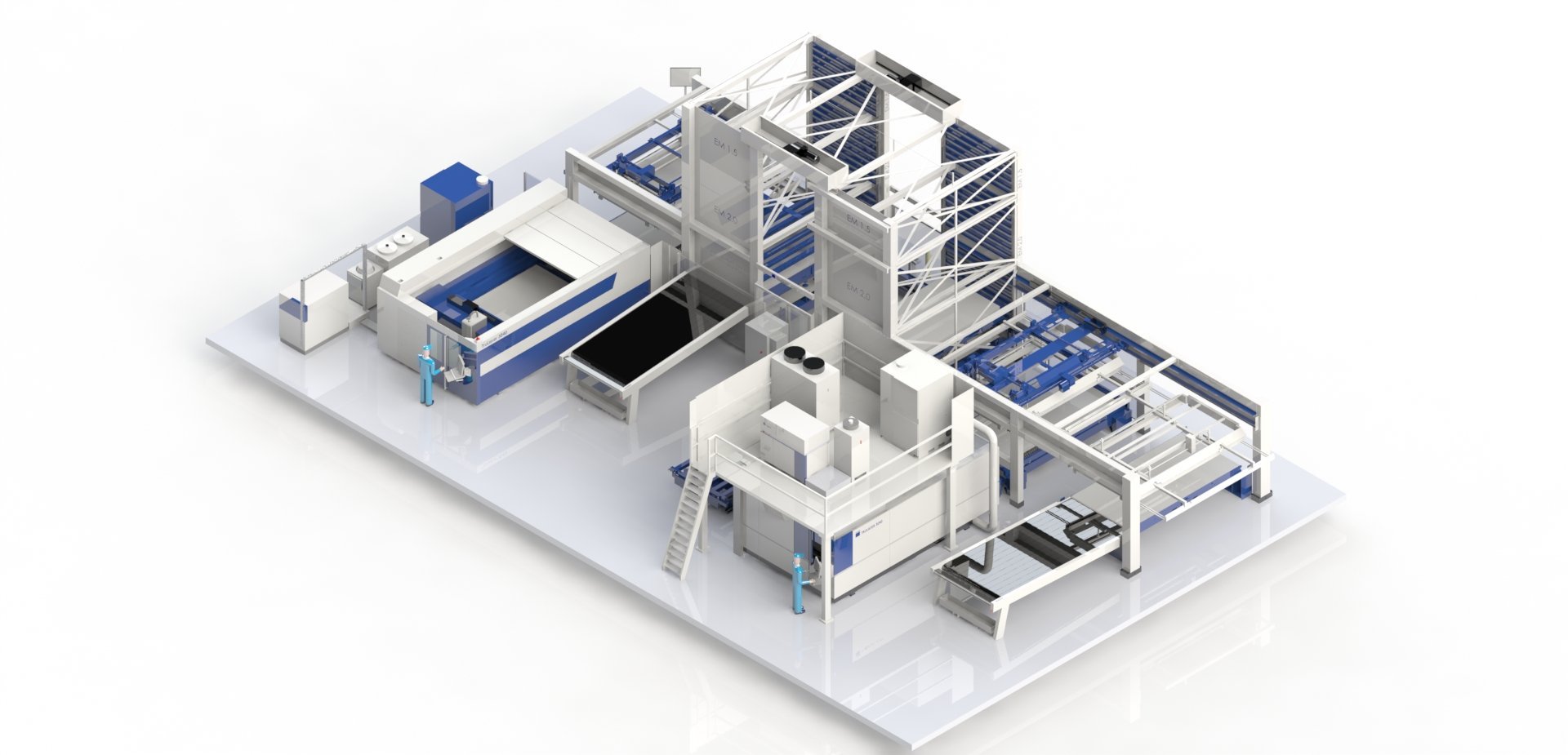

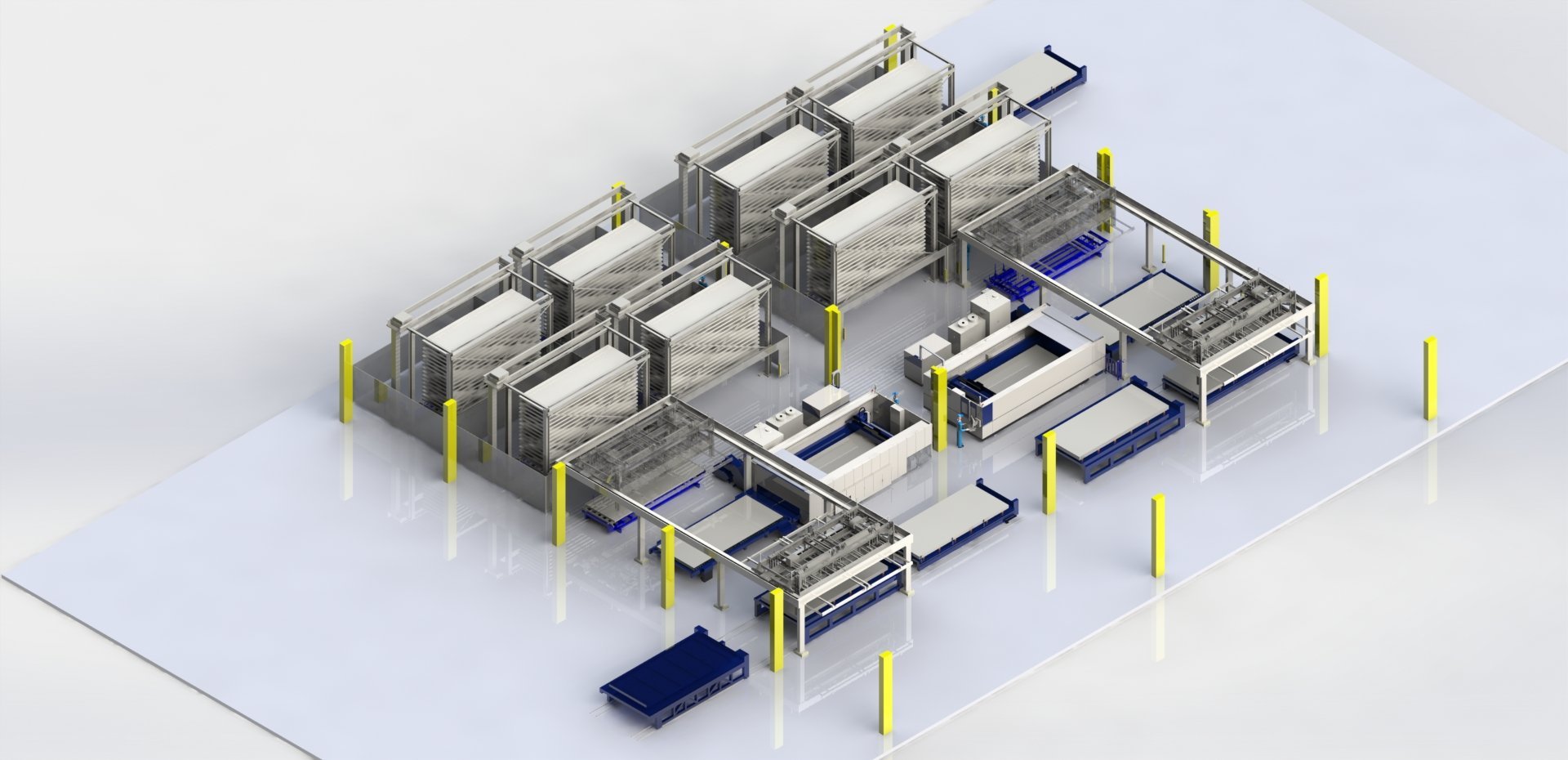

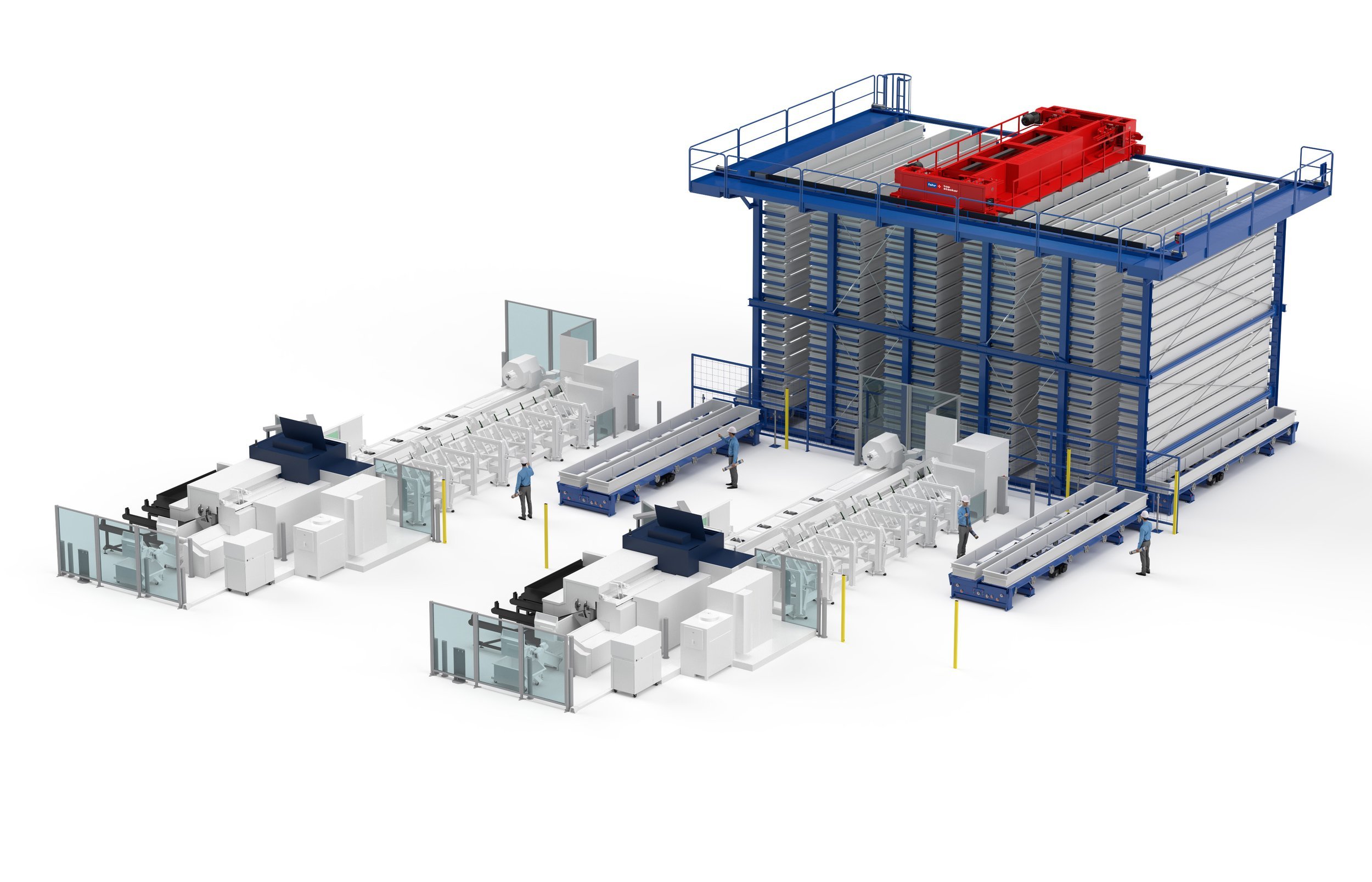

Speed. Power. Flexibility

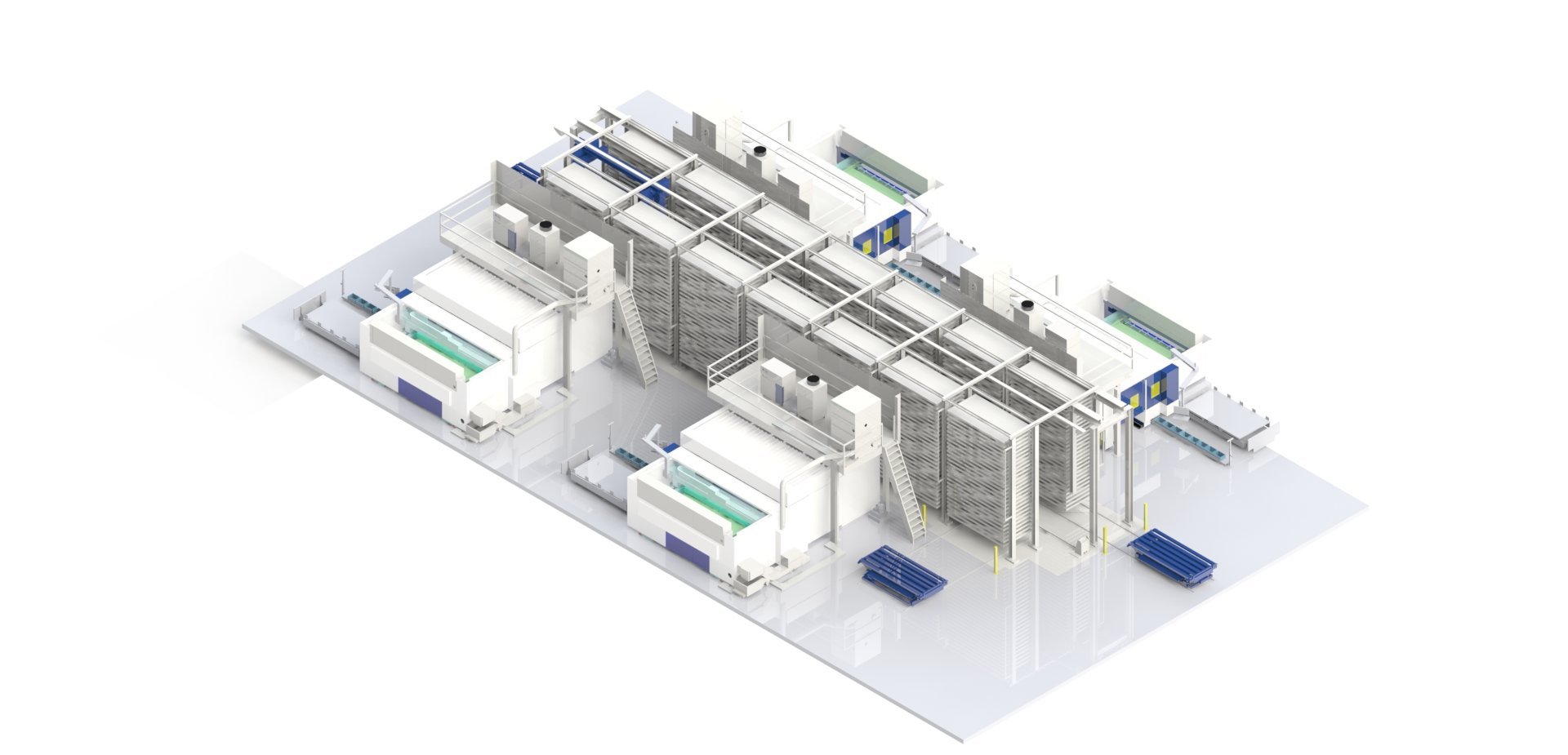

Increase your speed and throughput without increasing your error rate. From cutting, bending, & welding, to large-scale storage systems, a completely connected manufacturing environment can revolutionize a factory. Implementing automated machinery reduces manual errors and speeds up production. Smart automation ensures consistent quality and faster turnaround times.

Real-Time Data

Monitor KPIs across the entire production processes, from inventory, to an initial order, to the finished product, visibility is paramount. The consistent coordination of material and information, automation, and process allows for unparalleled growth and efficiency. Analyzing this data helps in making informed decisions to optimize production flow and reduce waste.

Reduce Time & Waste

Smart Factory connectivity helps reduce scrap rates and processing time while simultaneously boosting efficiency. Flexible manufacturing systems can produce customized orders without significant setup changes, reducing lead times and material waste associated with batch production.

Communication is Key

It all begins with a common language – a principle that holds true even for machines within the industrial Internet of Things (IoT). The smoother the flow of information, the greater the efficiency achieved. VDW and 16 other project partners have created a language called umati (universal machine tools interface). This is a universal interface that facilitates the secure, seamless, and easy integration of machine tools and equipment into tailored IT ecosystems.

Umati is the new global standard and introduces new possibilities for users across the globe during the Industry 4.0 revolution.

Modular and Scalable

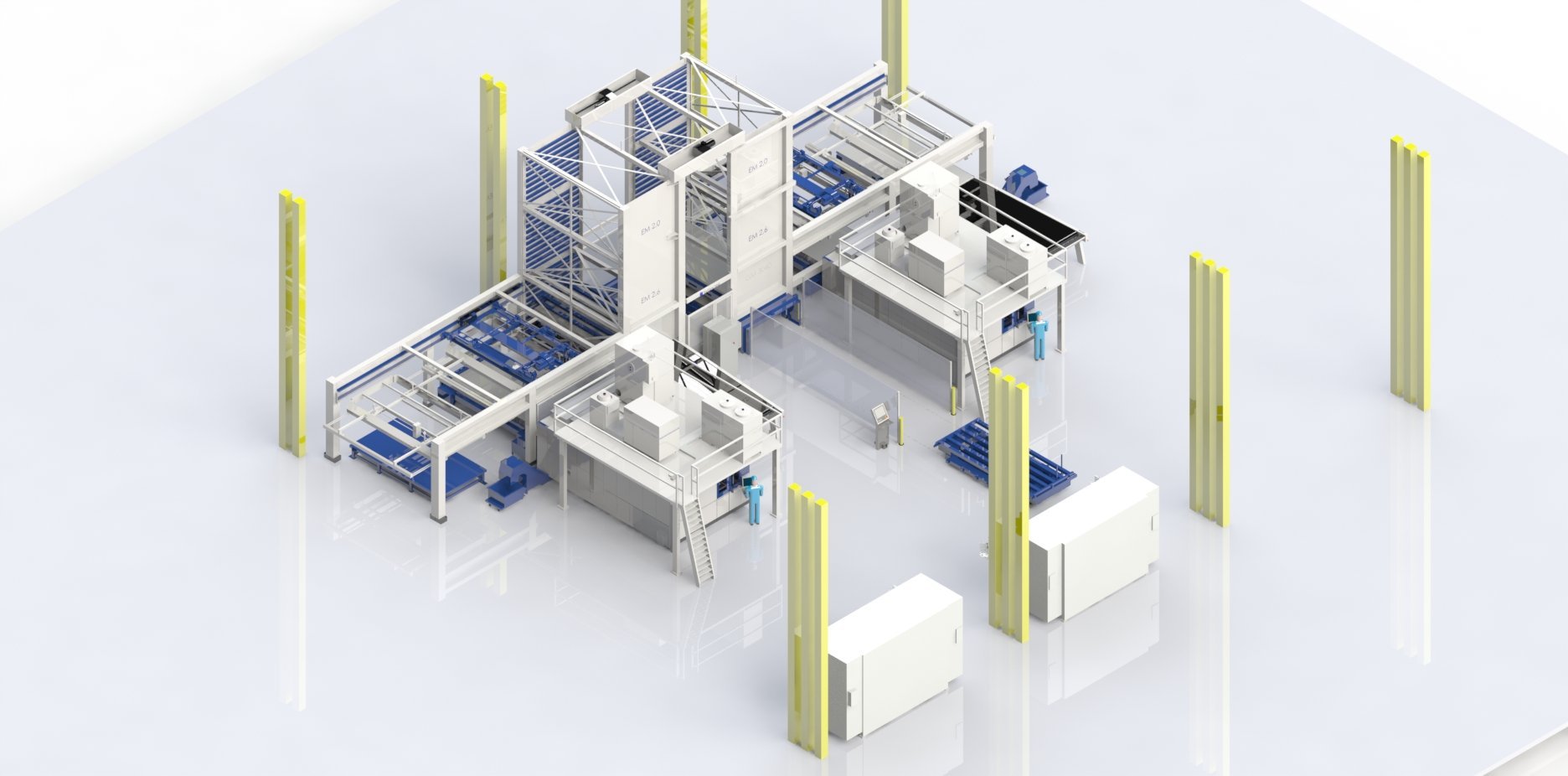

The first step toward a Smart Factory is cleaning up the “chaos” of your existing factory floor. Whether you’re looking for a complete overhaul, or simply looking to automate parts of your manufacturing process, Maintecx has a proven track record of deploying Factory 4.0 upgrades.

Smaller businesses may opt for an entry-level AI-based part removal assistant, whereas bigger organizations can set up complete semi-autonomous manufacturing that’s capable of punching, bending, laser cutting, and storage management.

Trump Smart Factory solutions can scale perfectly with your production needs. It’s designed to help metal fabricators equip their production facilities to their existing requirements, and leaves room to change and grow as the market changes and customer requirements evolve.

The Smart Factory of the future is already here. We’d be happy to tell you more.